Food recalls. No one wants to hear the words “food recall” because let’s face it, it’s a nightmare. Not only do you have to deal with the logistics of getting products off the shelves, but you’ve also got to handle the PR nightmare that follows. And on top of that, you’re left with a lot of wasted food and a lot of angry customers.

Take, for instance, you’re running a food production line, and you’ve been at it for hours. You’ve checked, double-checked, and triple-checked the packaging. Everything looks perfect. But after hours of work, the fatigue starts to set in. You miss a small crack in a bottle seal. It’s not a big deal, right? Just one mistake. But that one crack ends up costing you more than just a batch of defective products. You’ve got a recall on your hands, unhappy customers, and, well, the headache of cleaning up a mess that could have been avoided.

It’s frustrating, right? But what if you could avoid these issues before they even happen? What if you could spot those cracks (literal and figurative) before they go out the door? Well, here’s where AI-powered quality control comes in. It’s making waves in food production, and for good reason. It’s changing the way we do things in food production, and it’s time to seriously consider how it could improve your production line. Here’s how AI eases quality control in the food industry and why you need to pay attention.

Why Defects and Recalls Happen in the First Place

Before we get all excited about AI, we need to understand why defects and food recalls happen in the first place. It’s not as simple as just “checking” a product; there’s a whole system in play. Here’s a look at what’s really going on.

1. Human Error

Let’s be honest: humans make mistakes. Even the best workers in the food industry can miss a defect now and then. It could be something small, like overlooking a crack in a bottle or missing a mislabelled product. These things happen, but when they do, it can lead to major problems down the line.

Example:

Imagine a worker checking the seals on a bottling line. They’ve been doing this for hours, the line is moving fast, and fatigue sets in. One little bottle gets overlooked. That’s it—just one bottle. But guess what? That bottle makes it out, and suddenly, the entire batch is at risk for contamination. A recall follows, and now you’re left dealing with the fallout.

Solution:

This is where AI comes in to ensure quality assurance in food industry. AI doesn’t get tired. It doesn’t miss small cracks, mislabeling, or defects. Powered by computer vision and machine learning, AI can scan every single product, checking for defects faster than any human could, and more importantly, more accurately. It doesn’t miss a beat.

2. Equipment Failure

Machines are great until they’re not. A faulty piece of equipment can cause defects and problems that may not show up until it’s too late. A broken conveyor belt, a miscalibrated sensor, or a machine malfunction can throw off an entire production process.

Example:

Let’s say a sensor on the production line starts to malfunction, but no one catches it right away. Products get processed incorrectly. By the time the problem is noticed, thousands of units have been produced with errors. Now you’re looking at a recall.

Solution:

AI can monitor your equipment in real-time. It watches for signs that something’s wrong before it causes a big problem. Whether it’s detecting unusual vibrations in machinery or noticing temperature fluctuations that could lead to defects, AI steps in and warns you before disaster strikes. It’s like having a safety net that’s always on guard, making it the perfect addition to your food quality management process.

3. Inconsistent Standards

In the food industry, standards need to be consistent. Food quality control is a must. If different production lines, even different shifts, are applying different processes, things can get messy. It’s easy for things to slip through the cracks when standards aren’t consistently applied across the board.

Example:

Imagine two plants making the same product. One uses slightly higher temperatures in the cooking process. It doesn’t seem like much, but over time, that small change can lead to inconsistent product quality. And before you know it, a recall happens because one batch didn’t meet the standard.

Solution:

With AI, you get consistency at every step of the process. AI keeps track of critical factors like temperature, time, and ingredient proportions. It is an essential component of quality management systems in the food industry today. If something starts to drift from the ideal range, the system catches it instantly and alerts the team. Everything stays uniform, no surprises.

4. Supply Chain Issues

Not all defects start in the production line. Sometimes, the problem is with the raw materials. If suppliers don’t meet quality standards, it could affect the final product and you won’t know until it’s too late.

Example:

A batch of lettuce arrives at the production plant, but it hasn’t been properly washed. The contamination goes unnoticed, and that batch of salads gets sent to stores. A few days later, a recall happens because customers are getting sick from the contaminated product.

Solution:

AI can help monitor the supply chain and track the quality of raw materials from the moment they enter your facility. Sensors and smart devices can keep tabs on things like ingredient temperature and moisture levels, making sure nothing gets past quality checks. If there’s a problem early on, AI can help catch it, preventing contaminated ingredients from making their way into the final product.

5. Lack of Real-Time Data

Traditionally, data collection in food production isn’t immediate. Manual checks or delayed data updates can cause delays in identifying issues. This leaves room for errors to go unnoticed for too long.

Example:

A factory might manually log temperature readings every hour, but by the time the data is reviewed, an error has already caused a batch of food to go bad, costing the company a lot more than if they’d caught it right away.

Solution:

AI constantly monitors and analyzes data in real-time. Whether it’s machine performance, temperature, or humidity, AI keeps track of everything, giving instant insights into production processes. When an issue arises, AI alerts the team immediately, allowing them to address the problem before it escalates.

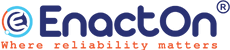

How AI Is Changing the Game for Food Inspection and Safety

So, we know the issues, but how does AI in food industry actually solve them? It’s not just about automating things. AI brings a level of speed, accuracy, and consistency that’s hard to beat. Here’s how it’s changing the food production process.

1. Faster, Smarter Inspections

The traditional way of inspecting products is slow and labor-intensive. Human inspectors can only check so many items in a day, and even the best of us miss a thing or two. But AI? It’s quick, efficient, and accurate. With AI-powered vision systems, you can inspect products in real-time as they move down the production line.

Example:

In a factory, AI constantly checks every bottle or food item as it passes by. Whether it’s looking for packaging defects, incorrect labeling, or contamination, AI catches it instantly. It doesn’t get tired, it doesn’t miss anything, and it does it faster than any human inspector could.

2. Predictive Maintenance for Equipment

You can’t always predict when a machine is going to fail. But AI can. By monitoring machinery, AI spots signs of wear and tear before they cause a breakdown.

Example:

In a meat processing facility, the AI picks up on a small vibration in one of the slicing machines. It’s not enough to stop production yet, but AI alerts the team to check it out before it becomes a bigger problem. That way, they fix it before things go sideways.

3. Automated Data Collection

AI collects and analyzes data in real-time, tracking everything from ingredient weights to oven temperatures. This constant data stream allows AI to detect patterns and anomalies that might not be obvious at first glance.

Example:

In a bakery, AI keeps track of the baking temperature, humidity, and ingredient weights. If anything is out of range, AI sends an alert, and the team can take immediate action to correct the issue. This means no more guessing and no more waiting for manual checks to catch problems.

4. Consistent Product Quality

AI ensures the consistency of every product. Whether it’s maintaining the same texture, flavor, or color, AI helps ensure every batch meets the same high standards.

Example:

In a beverage plant, AI can monitor the production process and make sure that each bottle is filled with the exact same amount of liquid. No underfilled bottles, no overfilled ones. Everything is perfect, every time.

5. Real-Time Problem Solving

With AI monitoring the entire production process, issues are identified and addressed as they happen. That’s a huge improvement over the old way, where problems could go unnoticed for hours.

Example:

A food manufacturer uses AI to monitor temperature control throughout the production process. If the temperature drops below a safe level at any point, AI triggers an alert and the team can quickly address the issue before the product is compromised.

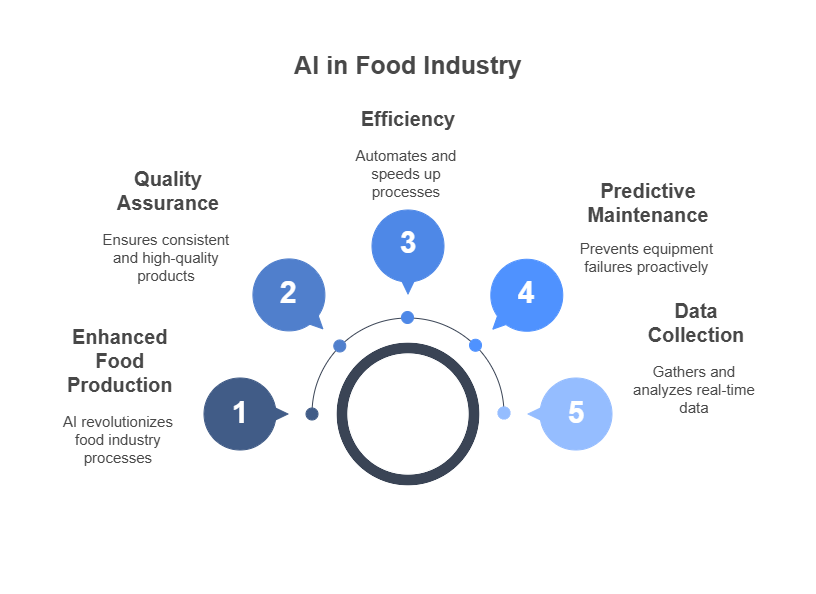

The Challenges of Implementing AI in Food Production

AI is great, but like anything, it’s not all smooth sailing. There are a few hurdles to overcome when implementing AI in food production.

1. Data Quality and Availability

AI is only as good as the data it receives. If the data is inaccurate or incomplete, the AI can’t do its job properly.

Solution:

Invest in collecting high-quality data from every part of your production line. This might mean upgrading equipment or adding sensors to monitor things like temperature, moisture, and ingredient quality. The better the data, the better the AI.

2. Initial Investment

AI can be pricey, especially at the beginning. The costs for hardware, software, and employee training can add up.

Solution:

While it’s a big upfront cost, AI pays for itself in the long run by reducing defects, preventing recalls, and improving efficiency. It’s an investment in the future of your business.

3. Integration with Existing Systems

AI needs to work with your current systems, not replace them. Integrating AI with existing equipment and processes can be tricky.

Solution:

AI can be customized to fit into your current production processes. A good AI partner will help ensure that the system integrates smoothly and doesn’t disrupt your operations.

4. Workforce Adoption

Some workers may be hesitant to adopt new technologies. Getting everyone on board with AI can be a challenge.

Solution:

Training is key. If your team understands how AI works and how it can improve their work, adoption will be easier. Show them the benefits firsthand, and they’ll be on board.

5. Maintenance and Upkeep

Like any system, AI needs regular maintenance to keep it running smoothly.

Solution:

Work with an AI partner who offers ongoing support and system updates to ensure everything keeps running as it should. That way, you can keep your focus on producing top-quality products.

Real-World Examples of AI Reducing Food Recalls

AI is already making a difference in food production. Here are a few examples of how it’s reducing defects and preventing recalls:

1. Dairy Industry

A dairy company started using AI-powered visual inspection to check for packaging defects. The system spots damaged seals and contamination before the product leaves the plant, reducing the chance of a recall.

2. Meat Processing

A meat plant used AI to monitor for foreign objects in their products. With AI’s help, they detected contaminants like metal or plastic before they left the plant, preventing a recall.

3. Bakery Production

A bakery-integrated AI to monitor oven temperatures and ingredient ratios. If anything goes wrong, AI sends an alert, allowing operators to make adjustments right away and ensure product quality.

How Enacton Can Help with AI Integration in Food Quality Control

So, is AI the future of food safety? Absolutely. And Enacton is here to help you get there. We specialize in AI-powered solutions that help food manufacturers streamline their production processes, reduce defects, and prevent recalls. Whether you’re looking to implement AI inspection systems or predictive maintenance, we can help make your production line safer, smarter, and more efficient. Visit our Foodtech Software Development Services to learn more.

AI and automation are only going to get better. The reality is, food production is becoming more efficient and safer because of it. So why wait for the future? You can start embracing AI now and stay ahead of the curve. The tools are there, and the benefits are clear. Whether you’re looking to reduce defects, prevent recalls, or improve your production line, AI is the answer. The sooner you start, the better.