Remember that time the avocados ran out right before Taco Tuesday? Or when the seafood special had to be pulled because the delivery didn’t show?

Restaurant inventory can be unpredictable and exhausting. Food costs spike. Waste piles up. “We’ll count it tomorrow” becomes a team motto. If it feels like inventory is a never-ending fire drill, you’re not alone.

At Enacton, we’ve worked with food businesses of all sizes—and nearly all of them shared one pain:

Lack of visibility into their inventory.

Here’s how to finally change that.

The High Stakes of Restaurant Inventory Management

Poor inventory control often leads to:

- Shrinking profits: Unused or expired stock is money down the drain.

- Menu inconsistencies: Frustrated customers when dishes are suddenly unavailable.

- Operational chaos: Staff scrambling, last-minute supplier calls, and breakdowns in the kitchen workflow.

And yet, with the right systems and habits in place, this chaos can be replaced by control.

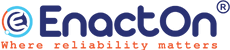

What is the Best Inventory Method for Restaurants?

There’s no one-size-fits-all approach—but a few methods stand out depending on your setup:

- Manual Inventory: Old school but still used by small operations. Prone to human error.

- Perpetual Inventory: Automated tracking that updates stock levels in real-time via your POS and inventory software.

- Just-in-Time (JIT): Inventory is purchased only when needed. Works best with reliable suppliers.

- Par Level Systems: Maintain minimum stock levels and reorder when you dip below.

Larger restaurants or those aiming for growth often combine methods and use software to keep everything aligned.

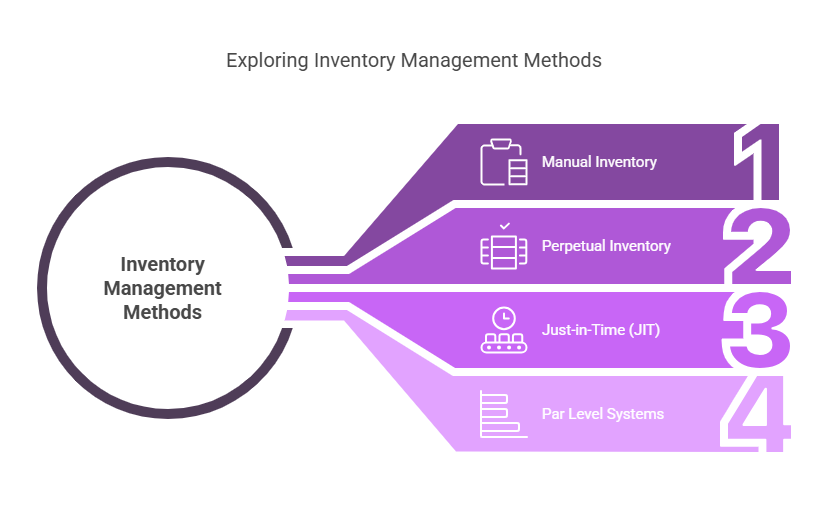

How to Keep Track of Restaurant Inventory

These practices set the foundation:

- Standardize recipes to ensure consistent ingredient usage.

- Pick a method—and stick with it. Whether manual or digital, consistency matters more than the method itself.

- Count inventory regularly: Daily for perishables, weekly or biweekly for others.

- Monitor food costs: Track your cost of goods sold (COGS) to highlight inefficiencies.

- Use technology: Inventory management tools drastically improve accuracy and cut down time.

At Enacton, we design custom dashboards so restaurants track inventory the way they operate—whether that means syncing with suppliers, flagging low stock, or forecasting demand.

What is a Good Inventory Turnover Ratio for a Restaurant?

A good ratio falls between 4 to 8 times per month. The higher the turnover, the more efficiently you’re using inventory.

Here’s the formula:

Inventory Turnover = Cost of Goods Sold / Average Inventory

Monitoring this helps you avoid overstocking, reduce waste, and respond to real demand patterns, especially when you can view it all from a clean, automated dashboard.

Inventory Costing Methods for Restaurants

How inventory is valued can affect both profit margins and taxes. Here are the most used methods:

- FIFO (First-In, First-Out): Ensures oldest stock is used first. Best for perishables.

- LIFO (Last-In, First-Out): Rare in restaurants, better suited to non-perishable goods.

- Weighted Average Cost: Spreads the cost evenly across all items.

- Standard Costing: Assigns a fixed cost per item.

- Market Costing: Updates prices based on the current market.

Your system should support the method that best aligns with your accounting and inventory needs—and be flexible if that method needs to evolve.

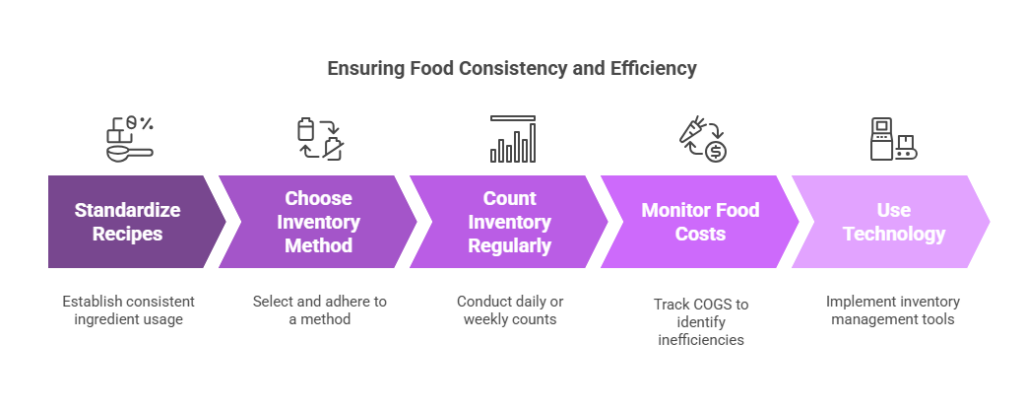

What are the 4 Main Steps in Inventory Management?

Simple in theory, often messy in practice—unless streamlined with technology.

- Planning: What to order, how much, and when.

- Purchasing: Placing and receiving stock orders.

- Storing: Proper shelving, labeling, and access.

- Tracking: Monitoring what comes in, goes out, and gets wasted.

Enacton’s food tech solutions are built around this cycle, making every step smarter, faster, and easier to manage.

Creating and Maintaining a Detailed Restaurant Inventory List

Inventory isn’t just about food—it’s about clarity.

- Categorize items by perishability, usage frequency, or station.

- Keep par levels and reorder quantities noted.

- Use clear, consistent labeling.

A detailed digital inventory list becomes your single source of truth, especially when multiple staff members manage it.

Inventory Receiving and Verification Process

Step one of inventory accuracy? Verifying deliveries.

- Check quantity and quality before accepting.

- Log it instantly (ideally, using a tablet or mobile interface).

- Flag discrepancies immediately.

Doing this consistently builds trust with suppliers and prevents back-office surprises.

Inventory Depletion, Variance, and Yield Analysis

- Depletion shows usage patterns over time.

- Variance highlights gaps between expected and actual stock, often due to waste, theft, or prep errors.

- Yield analysis helps calculate what portion of an ingredient is actually usable.

These insights uncover the “hidden leaks” in your inventory—and a good system tracks them all.

Staff Training and Accountability

Inventory success depends on the people managing it.

- Train staff on processes and software.

- Assign ownership of inventory zones.

- Implement dual verification for sensitive items.

Accountability improves accuracy, and accuracy protects profits.

Organizing Inventory Storage

Even the best inventory system falls short if your storage is a mess.

- Label shelves clearly.

- Keep high-use items within easy reach.

- Group items logically—by station, use, or perishability.

A clean, standardized layout saves time and reduces errors.

Automating Reordering and Demand Forecasting

No more guessing when to reorder.

With the right software, you can:

- Set reorder points per item

- Auto-generate purchase orders

- Forecast future needs based on historical sales and seasonal trends

Our custom systems at Enacton help you take the guesswork out of ordering, freeing up your team to focus on what matters.

Common Challenges and How to Overcome Them

Here’s what we hear most:

- “We keep running out of stuff.”

- “There’s too much waste.”

- “We can’t track what’s missing.”

Sound familiar?

The fix is a blend of:

✔️ Consistent procedures

✔️ Team training

✔️ Smart, integrated software

How Big Restaurant Chains Manage Their Inventory

It’s not just about budget—it’s about systems.

Chains like McDonald’s and Chipotle rely on:

- Centralized purchasing

- Data-driven forecasting

- Real-time inventory tracking

- JIT models to keep stock lean

The good news? With the right partner, even single-location restaurants can access this level of sophistication.

Real-World Examples and Case Studies

Chains use data to eliminate waste and maintain consistency across hundreds of locations.

One example: A cloud kitchen we supported used to track stock manually. After building a tailored inventory module, they saved 22% on monthly food costs and reduced waste by nearly half.

Best Practices for Effective Food Inventory Management

- Use the same staff for counts

- Log food waste daily

- Count perishables daily, dry goods weekly

- Follow FEFO (First Expiring, First Out)

- Track sell-through rates by menu item

- Set reorder alerts

- Regularly review variance and yield reports

- Train staff, monitor access, and set clear responsibilities

Why You Should Build Your Own Restaurant Management System

Out-of-the-box tools serve the average restaurant.

But your operations aren’t average.

A custom restaurant management system lets you:

- Tailor workflows to your kitchen

- Connect inventory to POS and accounting

- Control your data and avoid licensing bloat

- Build tools your team will actually use

At Enacton, we specialize in building custom foodtech software that aligns with your business and not the other way around.

Let’s talk about building your own system.

Final Thoughts: Take Control of Your Inventory Today

Inventory doesn’t have to be a black hole of waste and confusion.

With the right tools, training, and systems in place, it becomes a source of clarity and control.

Looking for smarter ways to manage your kitchen operations?

Enacton can help you build a custom restaurant management platform, purpose-built for your restaurant’s pace, needs, and future.

Let’s bring structure to the chaos.

Let’s build something better.